We need to know about OSH because:

- It is a requirement under the law (OSHA and its Regulations).

- We need to make provisions for securing the safety, health and welfare of our colleagues.

- We need to make provisions for protecting our clients against risks to safety or health in connection with our trade and activities.

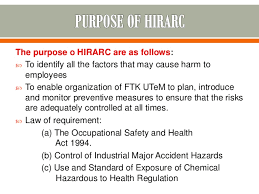

We need to know about HIRARC because:

- It is the core business of all OSH personnel, safety committee members, supervisors…etc.

- Before the proccess of identifying any hazards begin, it is necessary to know how to classify what is hazard, risk and danger.

- Hazard – anything that can cause harm.

- Risk – a probability of harm actually being done.

- Danger – the relative exposure to a hazard.

DEFINITION OF HIRARC

Hazard means a source or a situation with a potential for harm in terms of human injury or ill health, damage to property, damage to the environment or a combination of these. Hazard control means the process of implementing measures to reduce the risk associated with a hazard.

What is understood by the hierarchy of prevention and control measures?

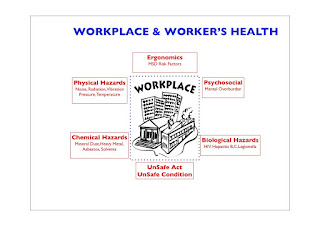

Risks may cause suffering to people, losses for companies and damage to our economy, and, as such, they should be avoided or – where this is not possible – reduced to a minimum. Common sense and legislation dictate that employers

assess the risks for their staff and implement related preventive or control measures. Preventive measures aim at avoiding risks whereas control measures are put in place in order to reduce and manage risks.

To combat the vast number of very different risks, for example slipping, falling, developing musculoskeletal disorders (MSD), radiation, stress, etc., researchers, technicians and practitioners have developed an even higher number of preventive and control measures. This means that employers need guidance in order to choose the most efficient measure. To facilitate this, measures are classified, e.g. as elimination measures, technical measures, organisational measures or personal measures, and these types are put into a hierarchical order. The highest level is seen as the most efficient one in terms of combating the risks. The lower levels are only to be applied, if no higher level measures are available, or if the application would be disproportionate in terms of effort and achievable result. In most cases, a package of measures should be applied, whereby the individual measures could be attributed to different hierarchical levels.

The importance of following the hierarchy

The importance of following a hierarchy becomes clear when looking at the following example, adapted from Stewart

[1]. A noisy machine is encased and insulated (technical measure). Otherwise the workers in the workshop would have to wear ear protection. However, not all workers always wear the protection, some ear protective equipment may not fit correctly, and others may not be worn in the stipulated manner. This will render the

personal measuresless efficient as compared to the technical measures. Nevertheless, technical measures also have their shortcomings. They may not be efficient enough as to allow workers to go about their work unprotected. They may be manipulated because workers regard them as interrupting their work process in an unacceptable way, or as too time consuming. Maintenance workers may have to do their job inside the encasing while the machine is running. Therefore, the best measure would always be to avoid or eliminate the hazard altogether.

Different hierarchies, legal requirements

Different hierarchies of prevention and control measures have been developed by different institutions. For an overview see e.g. Boyle

[2]. The BS OHSAS 18001 hierarchy can be seen as a typical system, as presented by Boyle:

- Elimination;

- Substitution;

- Engineering controls;

- Signage/warnings and/or administrative controls;

- Personal protective equipment.

The different systems have their advantages and their shortcomings; however, stakeholders should be aware of the legal requirements. These are in the first instance laid down in the EU ‘OSH Framework’ Directive 89/391 (see also:

Legislation), adopted in 1989 as ‘general principles of prevention’

[3]:

(a) avoiding risks;

(b) evaluating the risks which cannot be avoided:

(c) combating the risks at source;

(d) adapting the work to the individual, especially as regards the design of work places, the choice of work equipment and the choice of working and production methods, with a view, in particular, to alleviating monotonous work and work at a predetermined work-rate and to reducing their effect on health.

(e) adapting to technical progress;

(f) replacing the dangerous by the non-dangerous or the less dangerous;

(g) developing a coherent overall prevention policy which covers technology, organization of work, working conditions, social relationships and the influence of factors related to the working environment;

(h) giving collective protective measures priority over individual protective measures;

(i) giving appropriate instructions to the workers.

In other places, the Directive further explains the training needs and demands that ‘workers receive health surveillance appropriate to the health and safety risks they incur at work’.

The first system looks straightforward at first glance, however, it raises a common problem, namely that employers often see no possibility for elimination or substitution. Engineering measures are put in place (or even sometimes just personal measures) and little effort is put into reducing the hazards

[4].

The second system cannot serve as an easy tool for an employer at a small company as it would need some interpretation or closer scrutiny.

The Directive has, however, two clearly distinguishable hierarchical levels:

- Avoid the risks or eliminate the hazard

- Reduce the hazards and the risks

This means that an employer must not limit the control measures to e.g. encasing a noisy machine, but has to ‘combat the risk at source’ i.e. consider improving the machine, buying a new, less noisy machine, or searching for a different process that will reduce the emission altogether. ‘Adapting to technical progress’ is a continuous task.

The second step ‘Reduce the hazards and the risks’ has two implications, which are strongly interlinked, and this is unfortunately not really apparent in the first hierarchical system:

- If it is not possible to avoid the risks or eliminate the hazards, then the next step has to be to reduce/minimise the hazards AND separate the remaining hazards from the workers [5].

Thereby, for both strategies – reduction and separation – technical, organisational and personal measures can be employed, and ‘collective protective measures’ should be given ‘priority over individual protective measures’.

As has been indicated in the example in the second chapter, the manipulation of engineering controls is not uncommon: The German Social Accident Insurance DGUV established that approx. 37% of all safety appliances for metal processing machines in Germany are bypassed

[6]. In most cases, the reason is the time factor, i.e. workers feel disrupted in their work process or they feel under time pressure

[6]. Subsequently, the behaviour of workers has come into focus, and some institutions have complemented hierarchical systems by a further level of ‘behavioural oriented measures’

[7] , i.e. measures that aim to improve the safe behaviour of workers. These measures include such methods as peer-observation and peer-discussion and need preconditions, such as establishing a no-blame culture among managers and supervisors, and valuing proposals by diligent feed-back

[8].

Finally, all these measures need ‘appropriate instructions’ and

training, as well as possibly health surveillance, where risks cannot be avoided.